Guaranteed Fault Free For Life

Formhalls Vintage & Racing Ltd are worldwide suppliers of White Metal Bearing services to the restoration industry, engine manufacturers, Museums, machine shops, racers & private enthusiasts. All our bearings come with a lifetime guarantee against casting and material faults for the life of your engine.

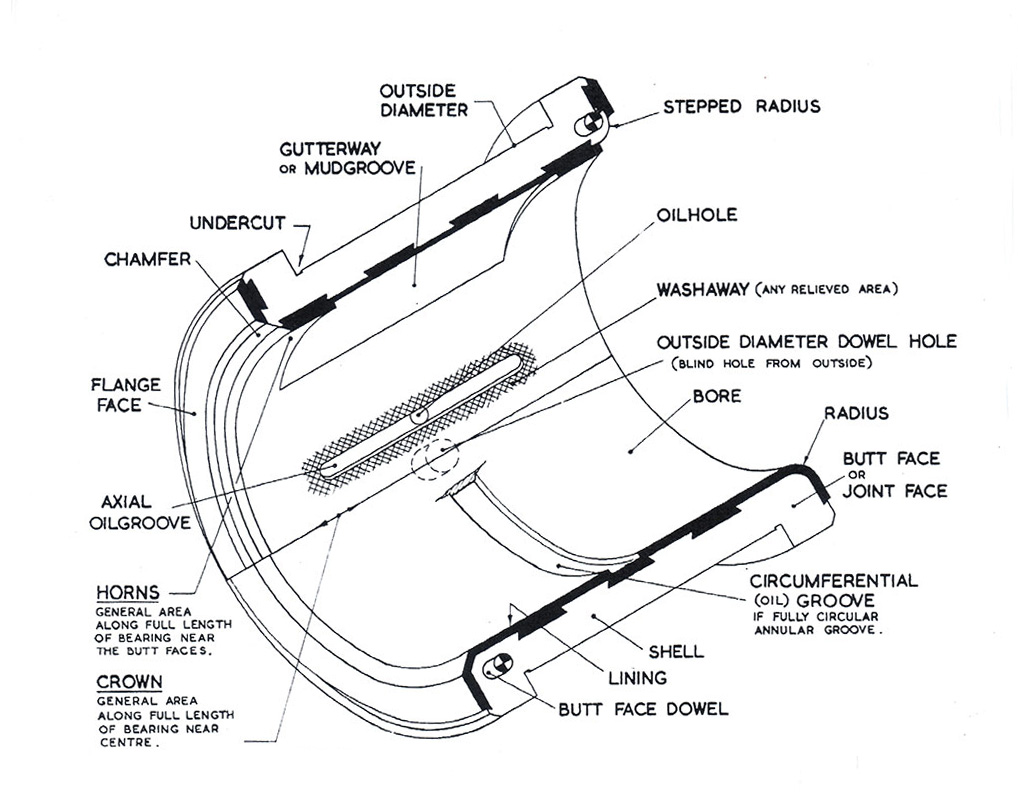

What Are White Metal Bearings?

A white metal bearing is a soft, anti-friction layer bonded to a hard backing of bronze or steel. Its purpose is to protect your crankshaft by allowing fine abrasive particles in the oil to embed below the surface, preventing crankshaft wear.

These bearings offer excellent resilience, absorbing high momentary overloads (such as during oil surge), and they adapt to minor misalignments—helping to avoid sudden failure. Even though oil cleanliness is important, white metal bearings are generally more forgiving than other bearing types.

One set of our bearings has completed over 60,000 miles of competitive driving—a testament to their durability

The Importance of a Proper Bond

For a bearing to perform correctly, the white metal must be uniformly bonded to its backing shell. If oil seeps between the lining and the shell, it creates an insulating layer, disrupting heat transfer and risking failure.

We use several proven methods to verify bond integrity:

- Ring Test

Tapping the bearing and listening for a dull tone, which may indicate poor bonding.

- Dye Penetrant

A two-step dye system that can highlight surface cracks or defects.

- HOYT Bondmeter

Our preferred method. It measures electrical current through the shell to detect weak bonding areas.