- 1000 views

At Formhalls, our in-house machine shop blends traditional craftsmanship with cutting-edge precision engineering. Whether restoring rare vintage engines or machining bespoke components for modern performance applications, we support projects across land, sea, and air. With fast turnaround times, competitive pricing, and an unwavering commitment to quality, we are trusted by enthusiasts and professionals alike.

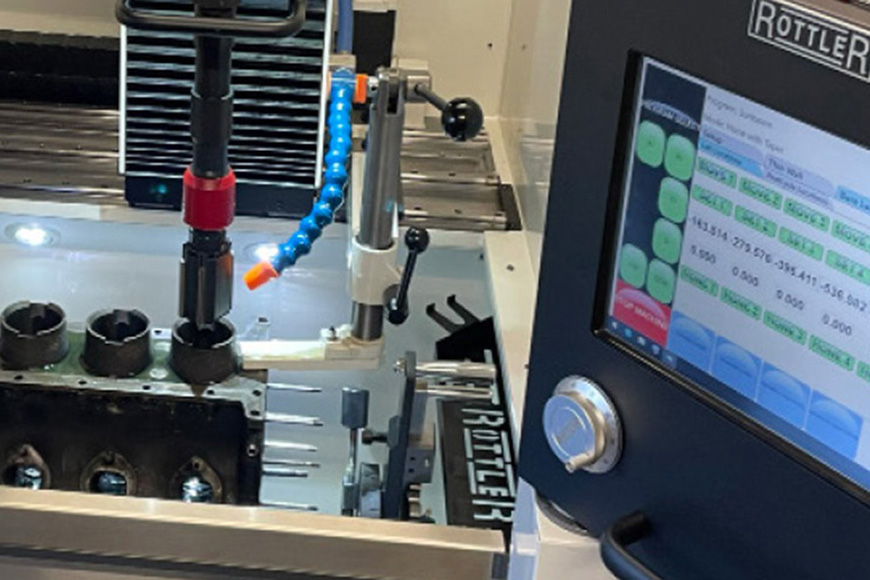

Advanced CNC Machining Capabilities

Our state-of-the-art CNC-equipped machine shop includes:

• Rottler H85AX Vertical CNC Honing Machine – Delivers exceptional bore accuracy and surface finish for performance and longevity.

• Comec ACF 200 CNC Cylinder Boring & Milling Machine – Provides ultra-precise cylinder boring and block facing.

• Serdi Valve Seat Cutting Machine – Ensures exact valve seat geometry for optimal engine performance.

These advanced systems allow us to deliver greater accuracy, shorter lead times, and tailored solutions for both restoration and high-performance projects.