At Formhalls Vintage & Racing, precision machining and in-house bearing manufacture go hand in hand. Our line boring and rod boring services are carried out to exacting tolerances, ensuring critical alignments are fully restored — often to a standard exceeding the original factory specification.

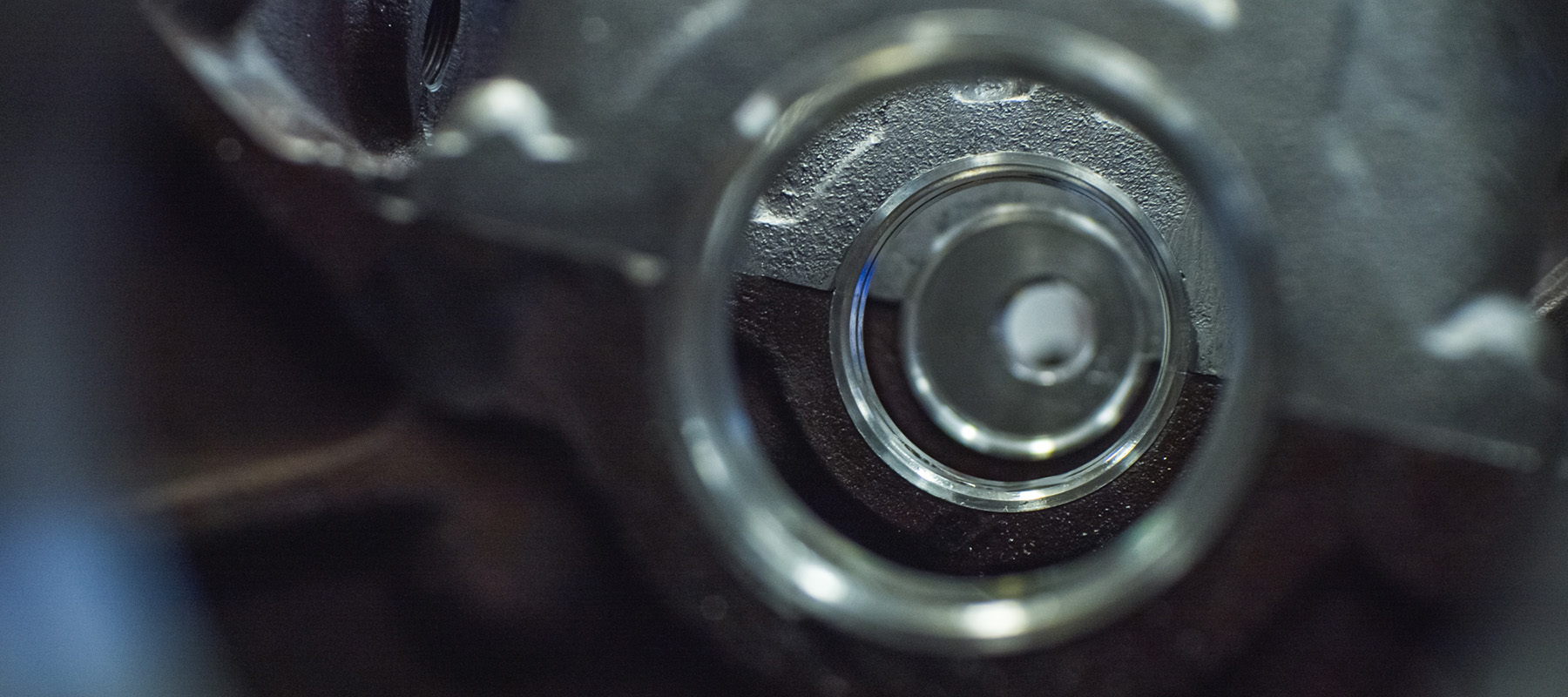

Line boring re-establishes the alignment of the main bearing housings, typically after distortion, wear, or previous incorrect machining. Once the block or crankcase is accurately bored, we manufacture and hand-fit new white metal bearings to suit. As one of the few remaining specialists producing white metal bearings in-house, we can ensure a perfect match between the restored geometry and the bearing material — improving load distribution, oil retention, and long-term performance.

Rod boring follows a similar approach. We precisely resize connecting rods and restore concentricity between the big-end and small-end bores. If required, we also manufacture and pour new white metal for big-end shells, achieving the exact clearances needed for smooth, reliable operation.

Our workshop combines traditional craftsmanship with modern accuracy. From one-off pre-war engines to rare competition units, each job is approached with the same commitment to quality and historical integrity — right down to the bearing material.